Shaping Solutions: Printed Parts in Action

October 7th, 2025

As October marks Manufacturing Month, Loureiro is proud to highlight how innovations like additive manufacturing are shaping safer, smarter solutions for our clients.

Within Loureiro’s Environmental, Health and Safety (EHS) service line, machine safeguarding is about more than compliance. It is about designing custom protections that keep people safe while maintaining productivity. Each project brings different machines, different risks, and different conditions. Meeting those needs has often required on-site cutting and fabrication — effective, but messy, time-consuming, and difficult to adapt if equipment or operations change.

When one client asked if there was a faster and cleaner way to achieve the same outcome, Loureiro responded by adding a new capability: additive manufacturing. By bringing 3D printing into the field, our team can now create precise, adaptable parts that improve safety and efficiency.

From Prototype to Practical Solutions

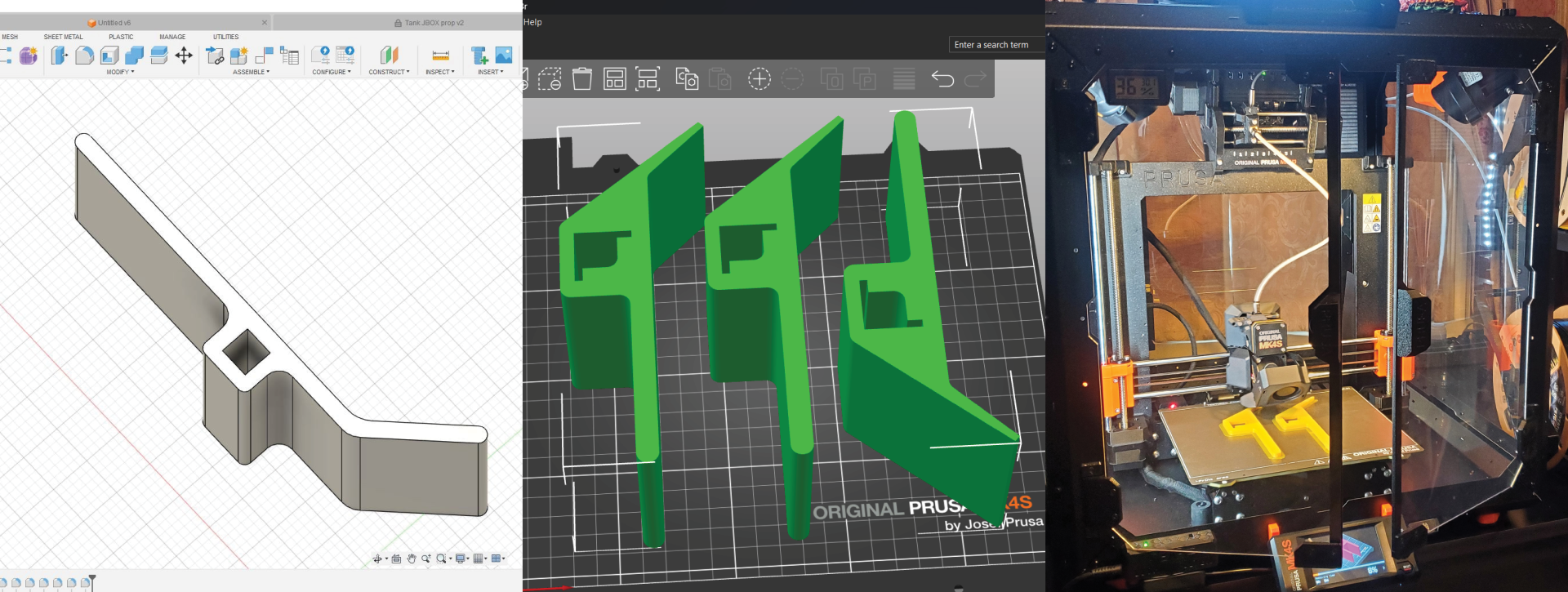

The idea began with prototyping. Instead of bending and cutting aluminum or polycarbonate to test a concept, Loureiro could model the design in CAD, send the file to a compact FDM printer, and have a plastic part in hand within hours. Prototypes could be tested directly on the machine, refined quickly, and reprinted until the fit and function were right.

In some cases, the results went further. The printed parts were durable enough to remain in service, giving clients a finished guard that reduced risk without slowing operations. What began as a way to mock up ideas is now a practical method for producing custom safety components on demand.

From field measurements to CAD to print, the process allows teams to move from concept to part in a single day.

Field Applications

The benefits of printed parts are already being realized in the field.

Machine guarding: On a roller line, Loureiro designed a rotating “flipper” guard that connects to a safety-rated switch. If contacted, the paddle shifts slightly and shuts down the machine. Printed in modular sections, the guard can be scaled to fit any machine width.

Wastewater treatment: Operators calibrating long pH probes needed a way to protect fragile sensor tips. Loureiro created printed baffles that guarded the probes, allowed water flow across the sensor, and doubled as a stand during calibration. The solution reduced strain on operators and avoided costly probe replacements.

Construction support: Instead of cutting steel templates to test hole spacing on brackets, Loureiro now prints lightweight models to verify alignment. Once confirmed, the CAD file is sent for steel fabrication, saving time and reducing material waste.

Material selection adds another layer of flexibility. PETG plastics withstand oils and coolants, carbon-fiber composites provide added strength, and antimicrobial options can support clean environments such as healthcare facilities. Each solution is matched to its setting.

(L) A modular “flipper” guard printed in sections connects to a safety switch, shutting down equipment instantly if contacted.

(C) A simple baffle printed for pH probes protects delicate sensors, reduces operator strain, and prevents costly damage.

(R) Lightweight printed templates confirm bracket fit and alignment before steel fabrication, saving time and materials.

Looking Ahead

Printed parts are now part of Loureiro’s toolbox for EHS projects and beyond. They allow our teams to solve problems more quickly, adapt solutions to client-specific needs, and deliver value in ways that traditional fabrication cannot.

This capability reflects Loureiro’s culture of innovation: applying technical expertise and practical creativity to meet challenges head-on. As applications continue to grow, additive manufacturing is helping us shape solutions that keep people safe, keep projects moving, and keep clients ahead.